Not just a green button

An inside look at OCDE's print shop

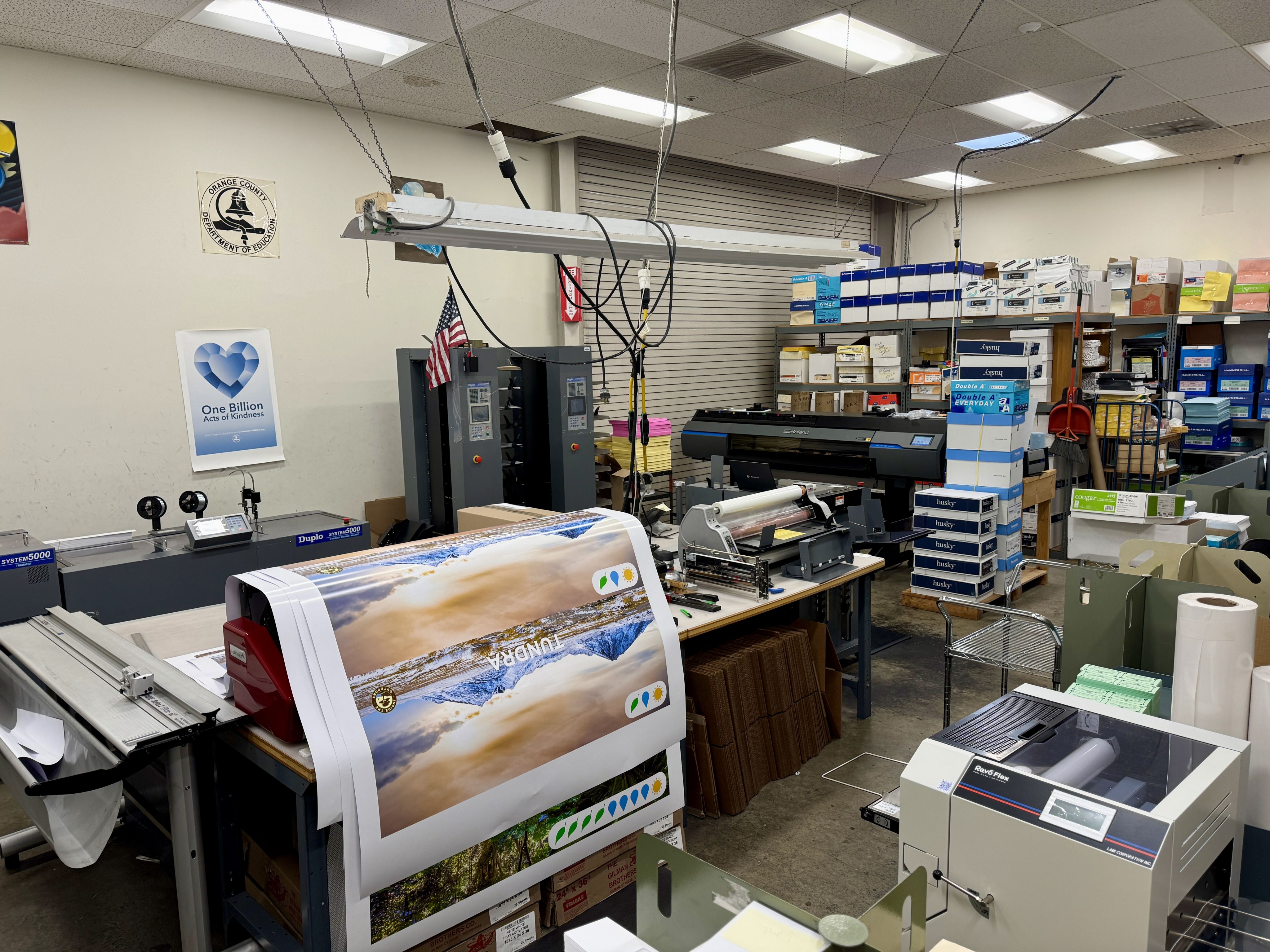

In an increasingly digital world, there's one place where paper still plays a crucial role: the Orange County Department of Education's Print Shop.

It used to be that every school district had their own print shop, but over the years, that number has slowly declined. However, every school still has a number of print requests — whether it's for school banners, fliers or even curriculum.

In the wake of this decline in print shops, OCDE's own Print Shop has taken on a substantial amount of print jobs throughout the county, in addition to its own printing needs. It even goes so far as to help outside organizations like local little leagues and churches with their printing needs. But when it comes to school printing, OCDE’s Print Shop is constantly in demand.

"You name it, we print it," said Shawn Black, OCDE’s reprographics supervisor.

One print shop...

Twenty-eight school districts in OC.

Turning stacks of invoices like this...

Into finished posters like this requires time and precision.

So how does a small print shop with only three full-time employees manage the majority of print requests for schools in Orange County?

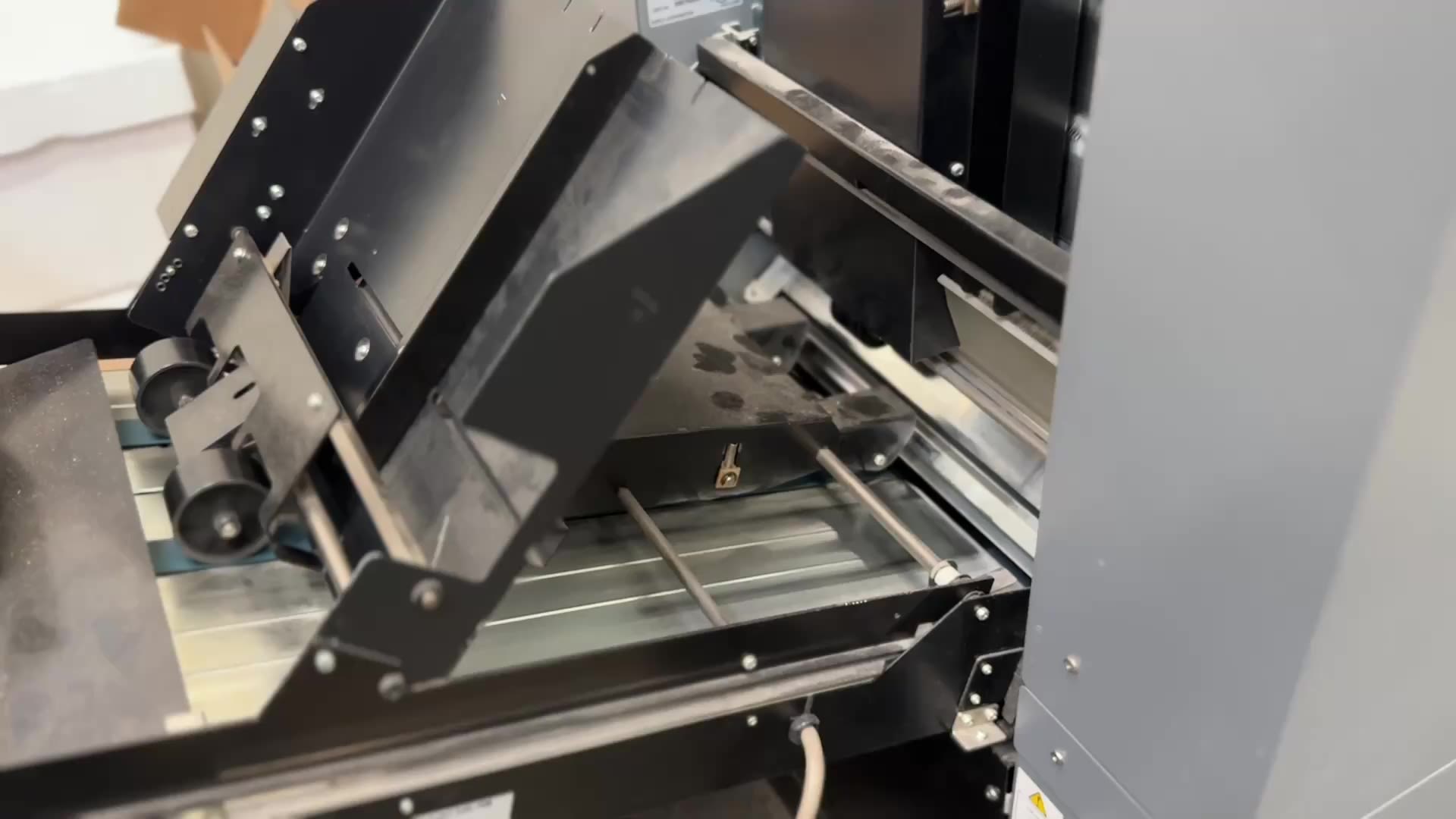

It starts with utilizing a variety of machines:

In-house orders from OCDE are entered into an online system, while external orders require a separate one.

Then the design is sent to the printer, where on average jobs can take between three to four hours to finish printing.

Cutting and finishing come next with the help of machines like guillotine cutters, helping make slicing through large stacks of paper slightly easier than using scissors.

Larger posters and banners require a special printer and take even longer to print.

While the printer and other machines may steal the show, each order takes more manpower than you might think. A lot more.

According to Shawn, jobs on average take between four and five hours to complete. Some larger orders can even take up to three weeks. But there’s no time for twiddling thumbs while those orders finish.

As they print, emergency orders will often arrive on a moment's notice, throwing a wrench in existing project schedules. Time management and asset allocation become a major part of the job — knowing which jobs to pause on one machine and which ones to start on another.

“If you have that much, you can’t just eliminate one machine all day long because you have so much other stuff,” Shawn said.

Then factor in machine maintenance, adding finishing touches on completed projects, and the packing and restocking of over 60 different print material styles, it's clear that working in the print shop isn’t as simple as pressing Command or Ctrl + P on a keyboard. In fact, there's a phrase that staff sometimes toss around in the shop, tongue-in-cheek.

“But we just press a green button.”

By the numbers

Print order sales summary from Jan. 1, 2025 to Dec. 10, 2025

Total in-house orders

1,857

Total district orders

950

Total orders

2,807

Quantity of items sold in-house through 2025

Quantity of items sold in-house through 2025

Behind every number is a small group of three ensuring the shop’s operations run smoothly.

Even for a seasoned veteran like Shawn, the volume of work can be daunting. Over the 27 years he’s worked in the OCDE Print Shop, he’s watched busy seasons stretch into a year-round operation as the district picked up more work — even as the number of staff declined.

Modern technology has streamlined much of the process, but the added volume has created a zero-sum situation.

“I haven't had a week-long vacation in over three years,” he said.

Then there’s Tony Franco, Shawn’s right-hand man, who was hired just over six months ago. While his prior experience working in a print shop has been helpful, he admitted that he’s still had to learn a lot on the fly. How to operate each machine and set it up properly for each project takes time — a luxury he and Shawn don’t have.

As Tony and Shawn fulfill each order, Joanna Muñoz keeps track of every financial transaction as a facilities operations technician and the print shop’s lone bookkeeper.

While invoices for in-house orders are generated automatically, outside jobs require Joanna to manually enter every detail, print job tickets and keep careful records. On top of billing, she manages purchasing requests, monthly budget reports and customer inquiries, keeping her just as busy year-round as the printers themselves.

With that constant pace, it would be easy to assume the Print Shop is a major revenue source for OCDE. But according to Shawn, that’s never been the goal.

“We’re not trying to turn a profit,” he said. “Just enough to break even.”

After all, OCDE is committed to serving students and schools across Orange County, where the print shop remains a critical part of that work — supporting classrooms and communities one job at a time.